YachtMech

Well-Known Member

So a few more updates, More sanding and coats of vanish inside but no point showing that again. got the first coat of 2 part Interlux interprotect in the machinery space. There needs to be a few sections that will be modified or filled in (like the old transom assembly bolt holes), but I wanted to get a sealing coat down on the new fiberglass before it got contaminated in any way.

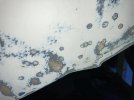

I also got around to scraping and sanding down the transom since I wanted to find every old screw hole and properly patch them. as you can see quite a few transducers have lived on this hull. I will be going to a through hull combined with the 3 in 1 from lowrance, however I will be attaching it to a starboard plate bolted to the new swim platform. I also drilled out every hole I could see that had been previously patched to investigate for any rot or moisture. Unsurprisingly there was some, I went ahead and drilled a few holes in a circular patter extending out from the area to find the limit, thankfully it did not extend too far. Given how thick the fiberglass is on this boat I wont be concerned with structural issues from this as long as it mitigated now. So next step will be temporarily plugging all the holes and sealing up any seams, then I will be putting the vacuum pump on the transom to boil away any moisture within the layers. Then I will be injecting some rotfix resin with a pressure pot while putting it under vacuum.

I also finished installing the though tubes and sealed up the limber holes, I happened to have some carbon fiber tube left over from another project that worked perfectly, cut them longer than needed and scuffed them with 40grit, then mixed up some Gelmagic and got them epoxied in place, these are simply to let any water that gets trapped outboard of the stringers to drain down into the bilge

Also with all the new woodwork we decided that the hull will be repainted to a dark blue, I had to do quite a bit of sanding to get everything on the lower part of the transom fair and still have SOOOOO much more hull to sand. Since there was some burn though The transom will be recoated with 2 coats of gelcoat first, then sanded back a bit to get a smooth surface in preparation for the new paint.

I also got around to scraping and sanding down the transom since I wanted to find every old screw hole and properly patch them. as you can see quite a few transducers have lived on this hull. I will be going to a through hull combined with the 3 in 1 from lowrance, however I will be attaching it to a starboard plate bolted to the new swim platform. I also drilled out every hole I could see that had been previously patched to investigate for any rot or moisture. Unsurprisingly there was some, I went ahead and drilled a few holes in a circular patter extending out from the area to find the limit, thankfully it did not extend too far. Given how thick the fiberglass is on this boat I wont be concerned with structural issues from this as long as it mitigated now. So next step will be temporarily plugging all the holes and sealing up any seams, then I will be putting the vacuum pump on the transom to boil away any moisture within the layers. Then I will be injecting some rotfix resin with a pressure pot while putting it under vacuum.

I also finished installing the though tubes and sealed up the limber holes, I happened to have some carbon fiber tube left over from another project that worked perfectly, cut them longer than needed and scuffed them with 40grit, then mixed up some Gelmagic and got them epoxied in place, these are simply to let any water that gets trapped outboard of the stringers to drain down into the bilge

Also with all the new woodwork we decided that the hull will be repainted to a dark blue, I had to do quite a bit of sanding to get everything on the lower part of the transom fair and still have SOOOOO much more hull to sand. Since there was some burn though The transom will be recoated with 2 coats of gelcoat first, then sanded back a bit to get a smooth surface in preparation for the new paint.