Charter Tofino

Well-Known Member

It was a 200 Suzuki. He said it was great but I don’t know what the performance numbers were.Thanks. What size outboard did your friend have and did he like it.

It was a 200 Suzuki. He said it was great but I don’t know what the performance numbers were.Thanks. What size outboard did your friend have and did he like it.

I was quoted $2k plus taxes. I wasn’t sure if that was too much or not.Probably in the $1500 range + or_ .

Seems about right. Nothing cheap anymore. However call around and get another quoteI was quoted $2k plus taxes. I wasn’t sure if that was too much or not.

That’s where you’re wrong, mrwood is cheapSeems about right. Nothing cheap anymore. However call around and get another quote

adventuremarine.ca

adventuremarine.ca

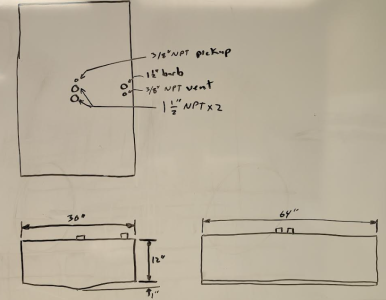

thicker material takes longer for electrolysis to burn through.I could use a little education here: why is wall thickness and issue for permanently installed aluminum fuel tanks? Easy to see that plate thickness matters for hulls, but if it's solidly mounted below deck and glassed in, is there really much point in 3/16" over 1/8"? Aren't the welds be the critical part? Molded poly tanks wouldnt even be 1/8" thick from what I've seen.

Not being critical here, just wondering.

From what I can tell min thickness is .090. Standard seems to be .125I was told 1/8 isn't legal anymore by the certified builder of the last tank I had done.

What are the little blocks of wood for in the back? Is that to hold the new plywood in place?Here are some pics from the fiberglass shop. Back deck stringers and transom will be new.

Lot of holes to fill.

View attachment 112977

This is looking towards the cabin. Motor mounts are coming out.

1st sheet of transom plywood. Will be 2nd one after this.