Rain City

Crew Member

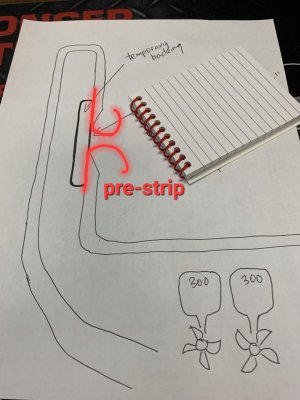

Bare with me guys, I’d like to confirm where the backing goes in your suggestions, View attachment 99504

Bare with me guys, I’d like to confirm where the backing goes in your suggestions, View attachment 99504

What’s the point of the prestrips in this case?

You said something about wanting to glass it all in at the back. I don't know man!What’s the point of the prestrips in this case?

Yea, that’s y I wanted to sandwich the ply to the existing deck, so It’s bonded there.You said something about wanting to glass it all in at the back. I don't know man!

Just start. Thinking doesn't finish the jobYea, that’s y I wanted to sandwich the ply to the existing deck, so It’s bonded there.

Originally I thought rayvon wanted me to flip the backing ply from the back, to the face of the deck and glass from the back, which makes a lot of sense to me as I won’t have to f around sanding the face flush , like my sample, a smooth flush factory finish. The placement of the backing is what started all this confusion for me, hence the idea of doing the cabin wall like that didn’t make sense

That's a way better way imoProgress report

Spent 8 hours at work today… not sure how long of that I spent drawing, boy I love my job.

I did get something very important done and that was levelling out the boat on the trailer perfectly.

How I tackle this deck is very important, I know there’s ways to save a bunch of time instead of sanding for a week to make everything flush.

Also know it’s worth listening to someone with 30 years experience building boats, I’m sure they have some tricks to get the job done faster, better and with less work.

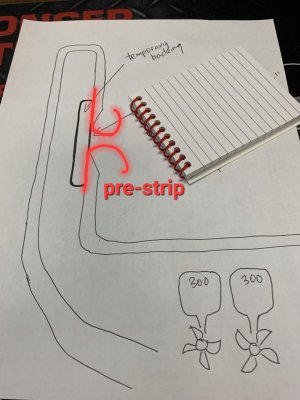

This is what I’m leaning towards now, gonna sleep on it and continue Monday View attachment 99513

That's what I was thinking too. They aren't staight whatsoever, plus you'll have the inside corners to deal with. Seems like a lot of work to maybe get portions of the face flat.It can be done either way.I understand your trying to keep the face as flush as possible without a ton of work fairing it out.My knowing how a mold is made with angled (5 degrees+ or-) so that the deck will release from the mold tells me that dropping the deck 6 1/2" they won't mate up in a straight line.Go at it which ever way you like, there will be some fairing required either way.I thought bevelling and glassing the front first would be easier than reaching up between the hull and deck.

Bolster pad?That's what I was thinking too. They aren't staight whatsoever, plus you'll have the inside corners to deal with. Seems like a lot of work to maybe get portions of the face flat.

Say what now?Bolster pad?

It's like putting a sticker over a repair job, it's just a bit more useful and expensive.Say what now?

Cleaning blood off vinyl is annoying too.It's like putting a sticker over a repair job, it's just a bit more useful and expensive.

“a sticker over a repair job”It's like putting a sticker over a repair job, it's just a bit more useful and expensive.

Seadeck!“a sticker over a repair job”

genius!

I think I have plan a and plan b now figured out

And a new name for your boat!!“a sticker over a repair job”

genius!

I think I have plan a and plan b now figured out

Like what?!?And a new name for your boat!!

See bolsters in photoCleaning blood off vinyl is annoying too.