sudsy

Well-Known Member

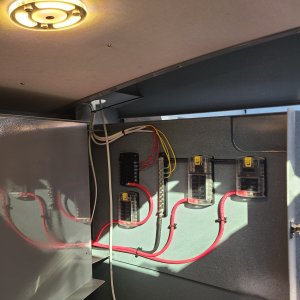

Once I took the boat home I made quick work of the backbone electrical system. It consists of a 200ah agm house battery bank mid ships and a starting battery in the rear cabinet. Both are tied to an acr at the rear cabinet with the starting battery. During the build I spent hours designing and planning the electrical - procuring the proper gauge wiring, connectors, circuit breakers and bus bars. It took just over a week to put in the backbone then I could start wiring individual components moving forward. I was fortunate enough to copy this design from a mutual friends boat with the same hull.