You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Did You Do To Your Boat This Week?

- Thread starter Stizzla

- Start date

SpringFever2359

Well-Known Member

Yes sir, installed 2 of them, I'm to "old" to be uncomfortable now lolLike the seat

Cabellas special ?

I wonder if their Bimini in a box would fit

not sure about the bimini

seachicken

Well-Known Member

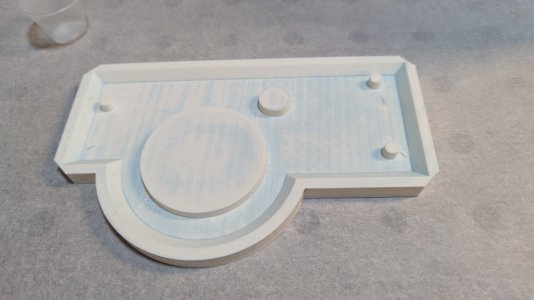

Nerdy things going on at my house tonight, 3d printing a mould for a 1/4" riser for my windlass... Will lay up some glass in it.

MRWood

Well-Known Member

Do you have the ping pong ball style scupper. A lot those you can see if they’re plugged or not. They can get pretty bunged up especially if you live near trees.Most satisfying thing, got the scuppers both working 100% after cleaning the boat and thinking, there must be more water that comes out, and there was! Coat hanger for the win.

kaelc

Crew Member

No I have the flap, there is a long tube and a dog leg (angle) as it exits to the side. Usually it blocks up just before or the angle.Do you have the ping pong ball style scupper. A lot those you can see if they’re plugged or not. They can get pretty bunged up especially if you live near trees.

Rayvon

Well-Known Member

Moved my batteries from transom to front of what was engine compartment,added the ACR system,Noco charger, breakers and fuse panel on transom for downriggers etc.. All new battery cables and wiring in back half of boat now. I'm going to install the SMG4 Suzuki gauges to the 200 and the 9.9 for troll mode etc.. About all that's left of the old boat rigging is the dash panel which I'll get to next year.

Stizzla

Crew Member

Let’s get you over to my place to do all that to mine when youre done! Free pizza and beverages!Moved my batteries from transom to front of what was engine compartment,added the ACR system,Noco charger, breakers and fuse panel on transom for downriggers etc.. All new battery cables and wiring in back half of boat now. I'm going to install the SMG4 Suzuki gauges to the 200 and the 9.9 for troll mode etc.. About all that's left of the old boat rigging is the dash panel which I'll get to next year.

Bearded wonder

Well-Known Member

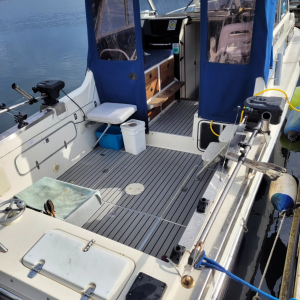

Well finally got the bugs figured out and second test run went great. A under-tightened water separator will ruin fun. Such a nice upgrade. Gets 11.6g/hr at full throttle (6000rpms and 36mph). Seems to cruise great at 29mph getting 6.6g/hr. Not sure how that is compared but probably a lot better that the 2 stroke.Got it delivered to Nanaimo today, mounting is Wednesday. Taking off the faithful 2 stroke this weekend. No motor pics as I didn’t want it at the shop with no protect View attachment 114854

Few more things to tidy up and then put all the gear back in. Then get some blood on the deck.

seachicken

Well-Known Member

Made a 3d printed mold for a little 1/4" riser for reworking my windlass mount. Layed up some glass in it after layers of mold release wax. Worked pretty good, in the end I put it in the freezer as it wasn't exactly popping out easily. It came out like an ice cube after though. I was worried molding in the holes was a mistake but came out great. I had assumed from the start I would have to destroy the mold in the end but it wasn't the case. I used polyester resin, first couple layers were 4 oz cloth because I had it, next couple pours were with 1/4" chopped strand.

Attachments

baddogg

Crew Member

You are going to love that motor. Bought the 115 Mercury 3 years ago. Plenty fast for my 542 and a fuel sipper too. So quiet. See you out therre.Well finally got the bugs figured out and second test run went great. A under-tightened water separator will ruin fun. Such a nice upgrade. Gets 11.6g/hr at full throttle (6000rpms and 36mph). Seems to cruise great at 29mph getting 6.6g/hr. Not sure how that is compared but probably a lot better that the 2 stroke.

Few more things to tidy up and then put all the gear back in. Then get some blood on the deck.

View attachment 115218

View attachment 115219View attachment 115220View attachment 115221View attachment 115222

kaelc

Crew Member

Great economy and top end! Looks dam nice.Well finally got the bugs figured out and second test run went great. A under-tightened water separator will ruin fun. Such a nice upgrade. Gets 11.6g/hr at full throttle (6000rpms and 36mph). Seems to cruise great at 29mph getting 6.6g/hr. Not sure how that is compared but probably a lot better that the 2 stroke.

Few more things to tidy up and then put all the gear back in. Then get some blood on the deck.

View attachment 115218

View attachment 115219View attachment 115220View attachment 115221View attachment 115222

Squire

Well-Known Member

Wow, that’s some tidy work there. Do you plan to glass that on to your deck or seal it on with 4200, 5200 or something similar?Made a 3d printed mold for a little 1/4" riser for reworking my windlass mount. Layed up some glass in it after layers of mold release wax. Worked pretty good, in the end I put it in the freezer as it wasn't exactly popping out easily. It came out like an ice cube after though. I was worried molding in the holes was a mistake but came out great. I had assumed from the start I would have to destroy the mold in the end but it wasn't the case. I used polyester resin, first couple layers were 4 oz cloth because I had it, next couple pours were with 1/4" chopped strand.

I was having problems with water ingress due to a poor windlass mounting job and I had to redo mine as well. I was somewhat proud of the job I did cutting a riser out of a 1/4” thick cutting board to seal onto the deck until I saw yours.

seachicken

Well-Known Member

Thanks, I will glass it down but I need to do a little surgery as there's exposed plywood between the windlass and the bow roller. It looks like whatever was there before was sealed to the deck and it broke away some fiberglass when it was removed. Once it's dry I'll take everything off and dig out any loose wood, apply some penetrating epoxy and then fill with layers of reinforced resin. All the holes through the deck will get drilled oversized and filled and redrilled to size (if there's any holes left going through plywood). I'm assuming there's some extra holes under the roller at least that will get filled. I figured making that doubler would nicely finish the deck over quite a bit of the repair area as well as shed water away so it's not relying on the gasket as much long term.Wow, that’s some tidy work there. Do you plan to glass that on to your deck or seal it on with 4200, 5200 or something similar?

I was having problems with water ingress due to a poor windlass mounting job and I had to redo mine as well. I was somewhat proud of the job I did cutting a riser out of a 1/4” thick cutting board to seal onto the deck until I saw yours.

Attachments

Squire

Well-Known Member

Good idea to seal the holes in the deck as well.

I have the same windlass so same holes for mounting but times 2 as they go through the bow pulpit and the deck and the inside edges were left exposed. They must have applied some kind of sealant though because there was no swelling of the core materials.

I have the same windlass so same holes for mounting but times 2 as they go through the bow pulpit and the deck and the inside edges were left exposed. They must have applied some kind of sealant though because there was no swelling of the core materials.

seachicken

Well-Known Member

Ya I'll definitely seal the bolts on installation.Good idea to seal the holes in the deck as well.

I have the same windlass so same holes for mounting but times 2 as they go through the bow pulpit and the deck and the inside edges were left exposed. They must have applied some kind of sealant though because there was no swelling of the core materials.

Squire

Well-Known Member

Yes, of course; I'm more concerned about the exposed edges of the 4" hole the anchor rode passes through.Ya I'll definitely seal the bolts on installation.

seachicken

Well-Known Member

Oh ya I'll cut back aft of that and it will be a 3" hole saw through fresh composite of some sort. Probably resin and chopped strand where the plywood core now is.Yes, of course; I'm more concerned about the exposed edges of the 4" hole the anchor rode passes through.

Similar threads

- Replies

- 35

- Views

- 2K

- Replies

- 10

- Views

- 1K

- Replies

- 20

- Views

- 2K

- Replies

- 6

- Views

- 724