You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do you fill holes in starboard?

- Thread starter Rain City

- Start date

ship happens

Crew Member

Nothing sticks to HDPE really. Bolts

Rain City

Crew Member

Maybe I should drill more speed holesNothing sticks to HDPE really. Bolts

ship happens

Crew Member

Holes equals drainage its ground fish season real soon. Go send it

Rain City

Crew Member

Can't wait to fill it up with dead stuffHoles equals drainage it ground fish season real soon. Go send it

Rain City

Crew Member

Nailed it.

ship happens

Crew Member

The season of things that once were are amongst usCan't wait to fill it up with dead stuff

mbowers

Well-Known Member

If you can make a groove in the outside edge of the hole the 5200 will be mechanically trapped in the hole. Do it on a really hot day and you might get some thermal expansion / shrinking working in your favour.Maybe I should drill more speed holes

Sounds like Marine Tex might stick especially if you flame treat the starboard first.

Did a repair on a plastic kayak with the West Systems epoxy kit for that purpose. It involved a flame treat to the plastic and that resulted in an impressively strong repair. But that stuff is snot coloured.

ship happens

Crew Member

Yeah 5200 and most other things dont do well in the UV. It all turns wierd. Looks nice for a bit. Ontop that nothing will actually stick to the HDPE. Mechanically binding to it would be a temporary solution and result in not nice clean up in a year or 2. It almost like trying to glue something to oil

Corey_lax

Crew Member

Durable Heavy Duty Rubber Fingertip Outdoor Entrance Mat, 24" x 32", Black https://a.co/d/cgTlU8W

Cut some of these to go overtop. It’ll hide the holes and the fishies won’t be sliding around on the slick surface

Cut some of these to go overtop. It’ll hide the holes and the fishies won’t be sliding around on the slick surface

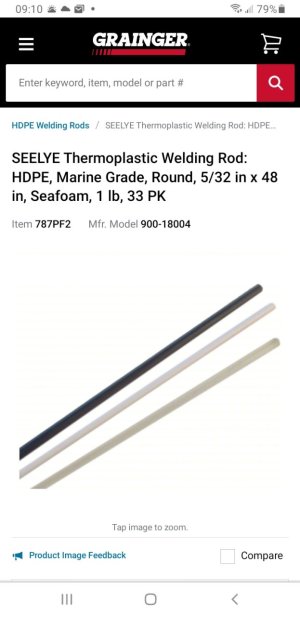

You can weld HDPE. It's standard practice in industrial settings. Most often done with specialised equipment but it's totally ok to use a soldering iron or heat gun with a small diameter reducing nozzle. You can buy filler rod or cut some small strips of starboard. Starboard strips are probably the best bet with your application. You won't have to worry about colour match that way. Also getting the exact match between filler and parent material is critical when welding plastic.

Like any weld repair, it's going to take skill to make it look pretty. Lay filler a bit proud and trim with a razor blade is probably the best bet.

Like any weld repair, it's going to take skill to make it look pretty. Lay filler a bit proud and trim with a razor blade is probably the best bet.

Rain City

Crew Member

Thanks! I called Nauti and tried to get an extra piece of material to make a removable front rail, but they said they don't stock any of this seafoam colorYou can weld HDPE. It's standard practice in industrial settings. Most often done with specialised equipment but it's totally ok to use a soldering iron or heat gun with a small diameter reducing nozzle. You can buy filler rod or cut some small strips of starboard. Starboard strips are probably the best bet with your application. You won't have to worry about colour match that way. Also getting the exact match between filler and parent material is critical when welding plastic.

Like any weld repair, it's going to take skill to make it look pretty. Lay filler a bit proud and trim with a razor blade is probably the best bet.

the fog ducker

Well-Known Member

https://buyindustrial.ca/ ? where i buy mine , in PocoThanks! I called Nauti and tried to get an extra piece of material to make a removable front rail, but they said they don't stock any of this seafoam color. Any idea where to get a scrap for welding?

BC Coast Pilot

Well-Known Member

easydoesit

Active Member

I used a hot glue gun to fill the holes in the platform for my boarding ladder about 10 years ago. Worked great, still looks good, no issues.

BC Coast Pilot

Well-Known Member

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 22

- Views

- 4K

- Replies

- 0

- Views

- 415

- Replies

- 12

- Views

- 7K