Andrew P

Well-Known Member

Hey Guys,

I need some feedback here...especially before I shell out a bunch of cash and time.

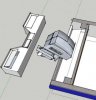

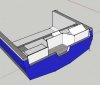

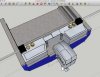

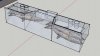

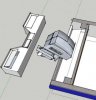

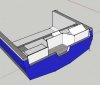

I want to build a cutting table/platform with some built in fish/prawn/crab well built in along with a couple bait wells. The idea is to have it sit into the splash well at the back. Note the squares on either side which are where my downriggers mount...but there was no downrigger model to plug into the mockup. I'll need to figure something out for the kicker too...but I don't generally fish off of it(only 2.5hp) so really just for safety.

Boat: 1625 Harbercraft Aluminum

Engine: 60hp Yamaha(need to leave space for it to lift and turn).

I figured making it out of aluminum would probably be the right move for durability and weight.

Here are a couple of pictures of what I am thinking soooooo far. I mocked it up in google sketch up last night to get a feel for it. I will certainly tweak the design and hope to get some good input from you guys.

Some other things that should be incorporated maybe:

Beer box

cup holders

center rod holder

gaff holder

ps....and if anyone knows of a welder who would be keen on helping me out with this project without taking all of my money...let me know!

Thanks!!

Andrew

I need some feedback here...especially before I shell out a bunch of cash and time.

I want to build a cutting table/platform with some built in fish/prawn/crab well built in along with a couple bait wells. The idea is to have it sit into the splash well at the back. Note the squares on either side which are where my downriggers mount...but there was no downrigger model to plug into the mockup. I'll need to figure something out for the kicker too...but I don't generally fish off of it(only 2.5hp) so really just for safety.

Boat: 1625 Harbercraft Aluminum

Engine: 60hp Yamaha(need to leave space for it to lift and turn).

I figured making it out of aluminum would probably be the right move for durability and weight.

Here are a couple of pictures of what I am thinking soooooo far. I mocked it up in google sketch up last night to get a feel for it. I will certainly tweak the design and hope to get some good input from you guys.

Some other things that should be incorporated maybe:

Beer box

cup holders

center rod holder

gaff holder

ps....and if anyone knows of a welder who would be keen on helping me out with this project without taking all of my money...let me know!

Thanks!!

Andrew