Just to throw this out there - how confident are you in your outboard mounting height?

I've been down this road on two vastly different boats. First boat I owned was a little Lifetimer with a 40hp Suzuki. The first ride was a huge diasappointment - bow was way up in the air, wouldn't plane at low speed, lots of spray off the motor - literally felt like I was dragging something through the water. Let me tell you - I was bummed, having just spend $25k on a custom built boat, and the builder is a ferry ride away. Anyway, It took it to a local shop - first thing they did was suggest the hydrofoil. Totally wrong move. It didn't solve anything - and created even more drag.

Then I started reading about how to mount an outboard correctly...

Long story short, outboard went up 2 holes (one hole at a time - lifted it myself using the trailer jack method), and added 2" of pitch to the prop. Boat flattened out beautifully, planed easier and at a lower speed, easily gained 5 mph, better fuel economy, better handling, etc, etc. Totally transformed the boat from a big old pig, to the nimble/delightful little boat I wanted. I fixed this by reading and doing the work - the shops were no help and just wanted to sell me stuff rather than put in the time. Shops feel like you want 'things' when what you really want is expertise. The only thing I was unhappy with was the fact that I'd caved by adding the hydrofoil and had drilled up my new Suzuki. The hydrofoil actually did have some benefits - the Lifetimer was a small boat and the foil actually stabilizes it quite a bit at speed - but that's not really going to happen on a big boat.

Fast forward to my second boat. 20ft Jasper centre console with an XL/25" 135 Evinrude. Boat already had 4 years and 150hrs under its belt, so you would think that the setup was dialed in. Absolutely was not dialed in - porpoised all over the place, zero ability to trim the engine at speed. This time I knew what to do: in the end the engine went up 3 holes to the very top mounting point. I still have the same prop on it, but could easily go up 1-2" pitch. Totally flattened out the porpoising - better fuel economy, vastly improved handling. Thankfully never added the hydrofoil. Did everything myself - lifted the big Evinrude using the trailer jack method.

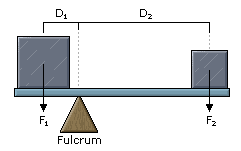

I say this with all respect: boat building is not the same as boat commissioning - two separate skills. Most outboards are mounted too low because its the conservative choice and lots of people won't know any better. You only really know a poorly rigged boat if you've experienced a totally dialed in boat. An outboard needs to be sea trialed with the boat loaded up the way you want it. First you adjust the engine mounting (one hole at a time). Only after the engine is mounted correctly can you proceed to step 2: experimenting with prop pitch / style. Playing with props before dialling in the mounting height is a great way to waste your money. Once you've done all of that - move some weight around. Only after that, and the boat is totally dialed should you start playing with tabs and foils. Tabs/foils just hide an underlying problem and kill efficiency.

Twin 250s...I suspect its beyond you to lift it in your driveway. What you can do to help out the shop (and prove that you have a problem): Take the boat out for a fast cruise on flat water with a buddy. Get them to hold the helm steady at speed, say 25-30mph (doesn't need to be flat out - just a comfortable fast cruise) with the motor trimmed as best you can. Go to the transom and take a video of the outboards so that you can see the side / rear - you need a clear shot of how water passes around the lower units. If the anti-cavitation plate isn't skimming the surface of the water - bam that's your problem, full stop. You cannot assess how a boat handles/performs when the outboards aren't mounted correctly. Don't start drilling holes for those foils until you get it mounted right. Once you have the video, you can show it to the mechanic. This can help them when they are assessing. Ideally you only want to lift the engines once - but be prepared to do it two time to get it properly dialed in.