Baxter

Well-Known Member

Thanks for the feedback earlier regarding my questions related to a fuse block.

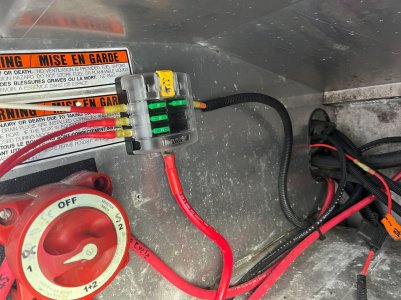

I have ordered a Blue Sea fuse block to replace my inline fuses and to replace a positive bus bar. Just a couple questions.

Along with my order I added Dielectric Grease. I have never used this before.

My understanding on how to use it is to essentially hook everything up then lightly coat all electrical connections with it.

I have also heard to use a small amount on my fuses before inserting them into the fuse block. Is this a good idea??

In addition I will put some on my negative bus bar as well and battery terminals.

So as far as the Dielectric Grease is concerned, does this all sound appropriate? Good idea?

I am also one of those paranoid people. My batteries are now 4 years old. I am debating replacing them - simply due to age. They have given me no trouble ever, and when not in use the boat is plugged into a charger/maintainer. Am I stupid to consider getting new batteries already? How many years does everyone tend to get?

Currently I have a two battery setup. Both batteries are virtually the same:

Both are always fully charged at home. I tend to alternate each trip which battery I use to hopefully even out their lifetime use. If the one I use happens to die, I will always have a full battery on board. (Have never had one die though) But if I should replace them, should I continue doing the same, or should I switch to a more dedicated cranking battery and a separate house battery? I see such conflicting reports everywhere on this! Perhaps the only wrong answer is to use both at the same time all the time (1+2) (I never do this btw)

I have ordered a Blue Sea fuse block to replace my inline fuses and to replace a positive bus bar. Just a couple questions.

Along with my order I added Dielectric Grease. I have never used this before.

My understanding on how to use it is to essentially hook everything up then lightly coat all electrical connections with it.

I have also heard to use a small amount on my fuses before inserting them into the fuse block. Is this a good idea??

In addition I will put some on my negative bus bar as well and battery terminals.

So as far as the Dielectric Grease is concerned, does this all sound appropriate? Good idea?

I am also one of those paranoid people. My batteries are now 4 years old. I am debating replacing them - simply due to age. They have given me no trouble ever, and when not in use the boat is plugged into a charger/maintainer. Am I stupid to consider getting new batteries already? How many years does everyone tend to get?

Currently I have a two battery setup. Both batteries are virtually the same:

| Battery 1 | Battery 2 | |

| Group | 24 | 27 |

| Cranking | 800 | 800 |

| Amp Hours | 79 | 80 |

| Minutes | 135 | 150 |

Both are always fully charged at home. I tend to alternate each trip which battery I use to hopefully even out their lifetime use. If the one I use happens to die, I will always have a full battery on board. (Have never had one die though) But if I should replace them, should I continue doing the same, or should I switch to a more dedicated cranking battery and a separate house battery? I see such conflicting reports everywhere on this! Perhaps the only wrong answer is to use both at the same time all the time (1+2) (I never do this btw)