You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

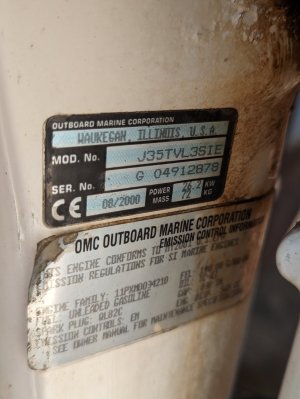

Johnson 35hp?

- Thread starter Redders

- Start date

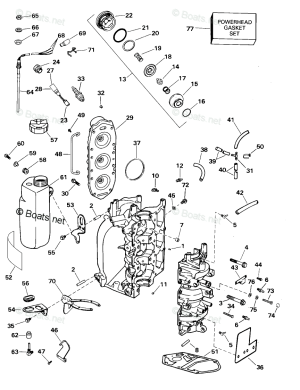

Try boat.net for pics. https://www.boats.net/catalog/johnson/outboard/35hp/j35tel3ssb-2000/fuel-system

Thanks - have the diagram off there but doesn't help me with assembly. Have sourced some 3/32 fuel line and Ts.

Attachments

ship happens

Crew Member

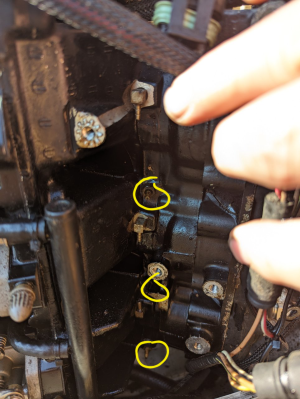

Pretty sure those are oil recirc hose barbs. On the 90 degree angle. I might have an engine on a pallet somewhere. It's possible. I can check tomorrow.It's the sequence of how these 6 nipples on the crank case are connected with the primer line I'm struggling with.

I'm pretty sure these ones are the primer

Last edited:

ship happens

Crew Member

You could technically just block off the oil recirc lines. Would not make or break anything. These had really terrible oil injection components and were usually bypassed. On the recirc, typically to be functional, they need check valves. Otherwise the fuel in a carbureted 2 stroke won't get blown into the cylinder properly because the air pressure will bleed to the next cylinder. It works but not my idea of how it should work

Last edited:

ship happens

Crew Member

I'm talking just cap the off right at the little hose barbs. Use the primer though in series. I'll see if I have one of those powerheads and take a quick peek at it. Possibility 50 percent. Might have gone for scrap

ship happens

Crew Member

Those primer solenoids are nice. Inject fuel right behind the reeds. Instant choke

You know what I should get to cap the oil barbs?Those primer solenoids are nice. Inject fuel right behind the reeds. Instant choke

ship happens

Crew Member

In the past I have inserted screws into the snubbed off lines with zip ties as clamps but you could use anything really as long as it's closed off and clamped with at least a tight zip tie

Thanks! Should I be zip tying the fuel lines onto those nipples as well?In the past I have inserted screws into the snubbed off lines with zip ties as clamps but you could use anything really as long as it's closed off and clamped with at least a tight zip tie

ship happens

Crew Member

Technecally no if the barb is aggressive enough. If the hose material expands and the barbs are sharp edged then I don't see then coming apart.

In fitting land they are called barbs not nipples. Even though most of us like one more than the other. Still called barbs lol

In fitting land they are called barbs not nipples. Even though most of us like one more than the other. Still called barbs lol

Seem to have have got as far with it as I'm going to get. Starts first crank cold in the morning and will run for a minute or two nicely and then cut out and won't start again. Did a compression test cold with all three plugs out and got 138, 128 and 132 across the three cylinders. Sounds like this is in the OK range? Got it booked into A and E marine to get checked out but it's a few weeks out. Anyone else to recommend in the Comox Valley or nearby for a Johnson?

Thanks

Nick

Thanks

Nick

ship happens

Crew Member

Within 5 percent is acceptable

ship happens

Crew Member

Might need the recirc lines. It might be pooling in the Reed cages. If it is, it will flood itself at idle after a long idle time

Without having to draw pictures and explain this. Here is a quick YouTube demonstration that's actually pretty well done. Kinda explains how it works. Need to make sure those hose barbs are indeed the right ones for the recirc to work properly

Without having to draw pictures and explain this. Here is a quick YouTube demonstration that's actually pretty well done. Kinda explains how it works. Need to make sure those hose barbs are indeed the right ones for the recirc to work properly

Last edited:

Similar threads

- Replies

- 0

- Views

- 184

- Replies

- 1

- Views

- 441

- Replies

- 2

- Views

- 945