Silvercreek

Active Member

Hi everybody

I've been lurking for a long time but I think this is my first post. I've been looking and enjoying some of the build threads on here and thought I would post my own of my latest boat build. My company is Silver Creek Marine in Salmon Arm, I figured this would help get me some exposure, hope that's allowed lol. This boat is being built on spec so if anyone is interested in buying let me know. I have a new mercury 200 hp 4 stroke that I will be rigging the boat with. Feel free to post any criticism or different ideas you might have, I'll try not too get too offended lol! The boat is nearly done the fabrication phase, I've got a few more days left. I'm trying to decide on if I should do any paint, vinyl wrap, hull liner, etc, and what if anything I want to put down for floor covering material.

Ok So I'll post a few pictures with a brief description of what's going on. I'm not sure how many pictures can be posted on what post, so I guess I'll find out now.

Here's some basic specs on the boat:

Bottom plate - 1/4" 5086

Sides, gunnels, cab - 3/16" 5086

Deadrise: 17 degrees stern, 18.5 degrees mid ship, 37 degrees at bow

Length overall - 23'

Beam - 8'6"

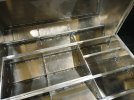

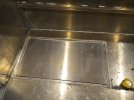

Rear deck length - 61" + 17" for box at the back (sink, storage, etc)

Length inside cab - 78"

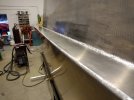

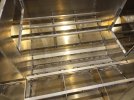

First couple pics here are of a few computer renderings, and the CNC cut pieces of aluminum

I've been lurking for a long time but I think this is my first post. I've been looking and enjoying some of the build threads on here and thought I would post my own of my latest boat build. My company is Silver Creek Marine in Salmon Arm, I figured this would help get me some exposure, hope that's allowed lol. This boat is being built on spec so if anyone is interested in buying let me know. I have a new mercury 200 hp 4 stroke that I will be rigging the boat with. Feel free to post any criticism or different ideas you might have, I'll try not too get too offended lol! The boat is nearly done the fabrication phase, I've got a few more days left. I'm trying to decide on if I should do any paint, vinyl wrap, hull liner, etc, and what if anything I want to put down for floor covering material.

Ok So I'll post a few pictures with a brief description of what's going on. I'm not sure how many pictures can be posted on what post, so I guess I'll find out now.

Here's some basic specs on the boat:

Bottom plate - 1/4" 5086

Sides, gunnels, cab - 3/16" 5086

Deadrise: 17 degrees stern, 18.5 degrees mid ship, 37 degrees at bow

Length overall - 23'

Beam - 8'6"

Rear deck length - 61" + 17" for box at the back (sink, storage, etc)

Length inside cab - 78"

First couple pics here are of a few computer renderings, and the CNC cut pieces of aluminum