kingblazer84

Crew Member

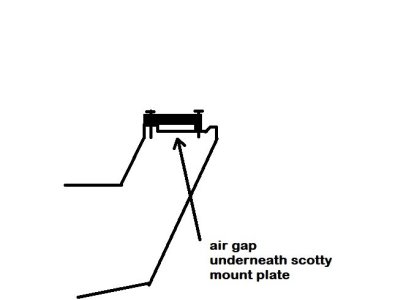

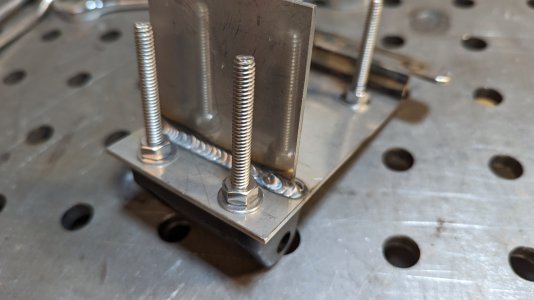

Ok, so im trying to finish my boat up here and trying to get my rigger mounting plates on my gunwales. I've hit a little snag and thinking of a couple options just seeing, if anyone thinks this idea of mine will work without putting too much stress on the top of gunwale. There is 2 raised edges inward and outward on the gunwale, and im thinking of bolting through the inner raised section then spacing with 1/2" starboard and bolting through the flat portion of the gunwale. Trying to not buy the scotty gunwale mounts if I can.

I've attached a crappy drawing of what im describing lol

I've attached a crappy drawing of what im describing lol

Attachments

Last edited: