Clarity of Processes:

DC Only Power Source-

- Stick, Tig, Spool gun Mig (wire feed) can do:

- DC Stick for ferrous and Stainless metals producing very high quality welds, aluminum stick is technically possible but in practice is atrocious lol

- DC Tig for ferrous metals, also Tig Brazing with Silicon-Bronze filler for kitschy stuff

- DC Mig (spool gun) for ferrous metals and aluminum, silicon-bronze wire for cast iron

DC Only Mig power source-

- Mig only for ferrous metals as above, need push/pull gun for aluminum unless using specialized machine such as Fronius or similar which can push only aluminum Mig

AC/DC Tig with AC Square wave

- Tig for ferrous metals, aluminum

- Stick for all of the above

Multi-process AC/DC square wave power source-

- All of the above Except AC Tig (may be some exceptions such as Fronius or similar

Notes:

If intending to stick weld steel and stainless, a 170 amp inverter machine of decent quality will do the job fine running 3/32” and 1/8” rod. I use the Fronius Transpocket 150 for quick field work.

Aluminum welding requires approximately 1.5 times more current than equivalent thickness steel due to rapid heat dispersion. A 150 amp DC Tig will comfortably Tig weld 1/4” steel plate, but a 150 amp AC Square wave will be quite limited welding aluminum

Tig welding steel is generally more difficult than Aluminum (depending on gauge), ferrous metals do not shed heat and so current must be ramped down as metal temperature increases.

Ask me anything I have so many welders

If you’re in Coquitlam I can show you what does what.

Clear Arc Shots & Plain Talk to help you Pass a Test, Fix Stuff, Build Stuff, Get a Raise, Build a Better Life. Disclaimer: These videos are intended for entertainment and inspiration. Welding is dangerous. Always seek professional advice and training before using welding equipment. If you...

m.youtube.com

If it were me and I wanted maximum flexibility with as few components as possible, I would choose the following:

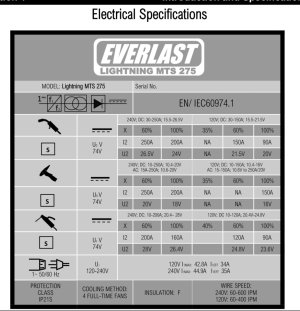

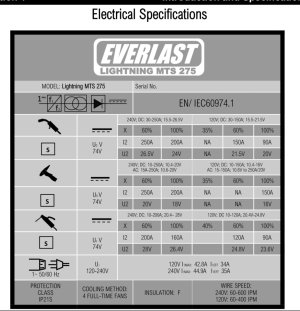

- 250 amp AC/DC square wave power source with stick electrode holder, and decent quality Tig torch with Tweco consumables. THIS IS THE MAXIMUM CURRENT YOU'LL BE ABLE TO PRODUCE USING A 50amp SINGLE PHASE 240v Circuit.

- Decent spool gun for aluminum wire feed 1 lb spools which allows for ferrous metal and aluminum welding

- Shielding Gas - Argon for Tig and Mig aluminum, Tig Steel and Stainless, as well as 75/25 Ar/CO2 mixed gas for Mig Steel. Rental gas bottles to start. It’s like 8$/month for K-size bottle plus cost of gas

- (1ea) 10 lb sleeves of 3/32” and 1/8” 7018 welding rod, I use ESAB OK 55 which is high quality rod. Welding rod is NOT all the same quality, so buy a sleeve of high quality rod to learn with. No sense struggling more than necessary.

- Electronic welding helmet with large viewing screen and readily available replacement lenses.

- Good quality clear safety glasses with UV A/B protection which will protect your eyes from projectile debris, but ALSO reduce or eliminate the risk of welding flash.

- Welding gloves (comfortable, not too thick)

- Chipping hammer

- 4 1/2” Grinder (for hiding your early work

)