Corey_lax

Crew Member

Well tis the season of failing air conditioners. My Ram truck, my Matrix, and my wife's Kia all had issues. I knew nothing about AC systems a month ago and I'm learning lots lately. The Kia is fixed, and now I'm sorting through issues on my 2006 Toyota Matrix. The AC starts blowing cold when engine is cold and then warms up over time as the engine warms up until the compressor eventually shuts off. Here's what I've done:

I think condenser might have a clog in it. It was warm in the passenger side upper corner, but very cool everywhere else. I'm not sure if this is normal.

I saw a small leak on the top of my radiator, so If I swap that out, I might just swap the condenser out at the same time.

Who on here knows how these magical air conditioning systems function?

- Checked fuses and relays --> All good

- Compressor turns on properly. Clutch gap is .6mm

- Refrigerant levels are good.

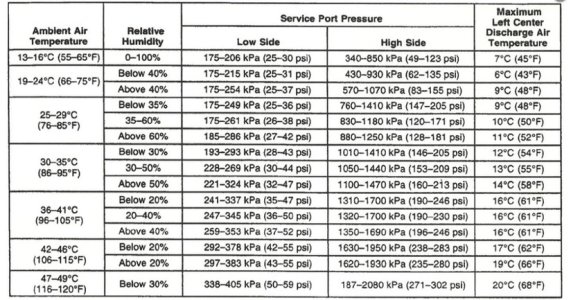

- Last night I started the car when the engine was cold. Ambient temperature was 18C/64F. The low pressure side started at 30psi, and high side started at 200 psi. After 20 minutes of idling, the low pressure side was very close to 0psi, and high side dropped to 170psi. What would cause the pressure to slowly drop like that? The compressor stayed running even at 1psi

- This morning I started the car when engine was cold. Ambient temperature was 13C/55F. Low side was at 18psi, high side was 170psi.

I think condenser might have a clog in it. It was warm in the passenger side upper corner, but very cool everywhere else. I'm not sure if this is normal.

I saw a small leak on the top of my radiator, so If I swap that out, I might just swap the condenser out at the same time.

Who on here knows how these magical air conditioning systems function?